Almost all companies in the electronics industry are affected by the component shortage: Various electronic components, from ICs to displays, are currently difficult or impossible to procure. The whole industry is struggling with material shortages. So do we.

As a manufacturer of individual HMI solutions, we depend on the reliable procurement of displays, touchscreens and electronic components. What do we do when these elementary assemblies are no longer available? We try to create alternatives! Alternatives that can be implemented without major changes at our customers.

Our customers can rely on us because:

We are not tied to any manufacturer

If a component is not available, we will of course take care of researching optimal alternatives. In doing so, we pay particular attention to ensuring that the replacement does not cause any major changes or requalifications for our customers. We are not bound to specific electronics manufacturers. This gives us access to a wide range of possible alternatives.

For frequently used display types in particular, we have direct recourse to a manufacturer in Asia who is still able to deliver. We have developed our own adapter solution for these alternative displays. Our solution allows our customers to continue using their existing interface without any problems. This allows us to replace a complete display family of a renowned manufacturer 1:1. We can also prevent time-consuming layout adjustments through our development.

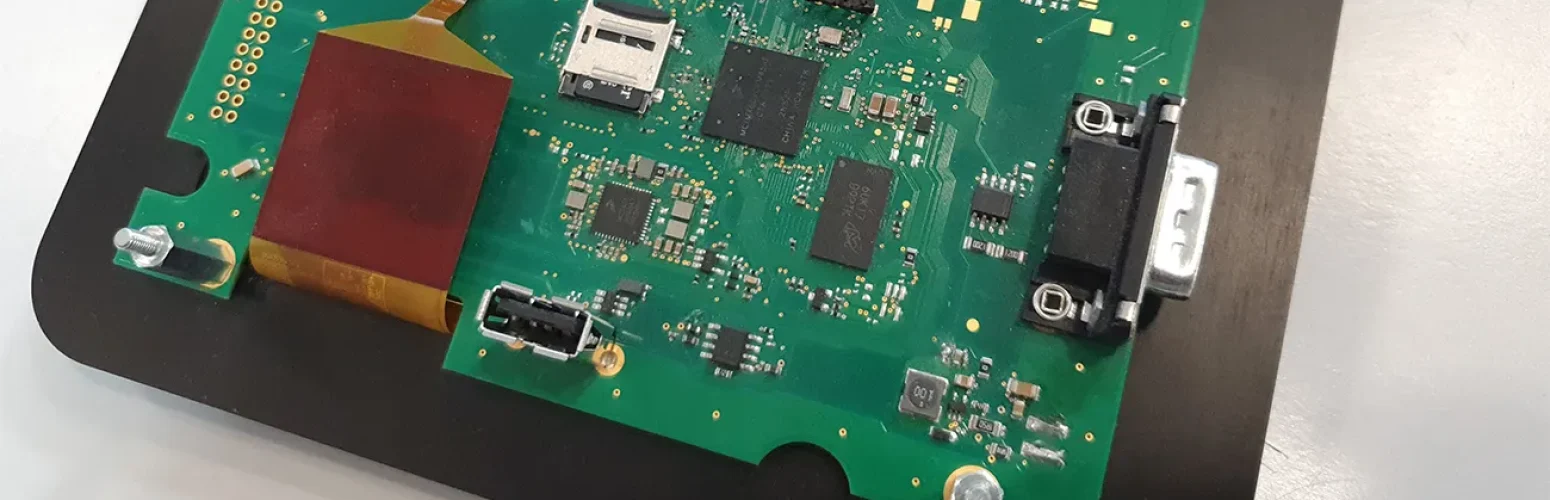

We have our own development and electronics manufacturing in house

We have developed many of our customer projects ourselves. This enables us to make the best assessment of which alternative parts and components are suitable. We are looking for comparable variants that can continue to meet all the requirements of our customers. However, if these are not available, we develop individual solutions. This is the only way we can keep the effort for customer-side changes as low as possible.

The biggest advantage is that we have our own in-house development and electronics manufacturing. This enables us to react quickly and independently to changed circumstances and to set up test setups if necessary.

We have a reliable change management

Constructive changes are regularly implemented by our team. For this purpose, we rely on a comprehensive and reliable change management system.

If no identical display type is available on the market, we quickly implement design changes. For this purpose, we test the mechanical and electronic components. We then coordinate the entire scope of changes with our customers. We adapt all design and manufacturing documents to the new version so that all changes are automatically included in the next order.

Should a component issue arise, we immediately sit down with our customers to mutually agree on a course of action:

What alternative components can be used?

Are major changes necessary?

What costs can be expected?

When can we deliver?

Do you have questions about your project or would you like to start a new project with us?

Contact us! Just send us your message or call us at +49 6281 5200 0.